What is a Hot Air Rework Station?

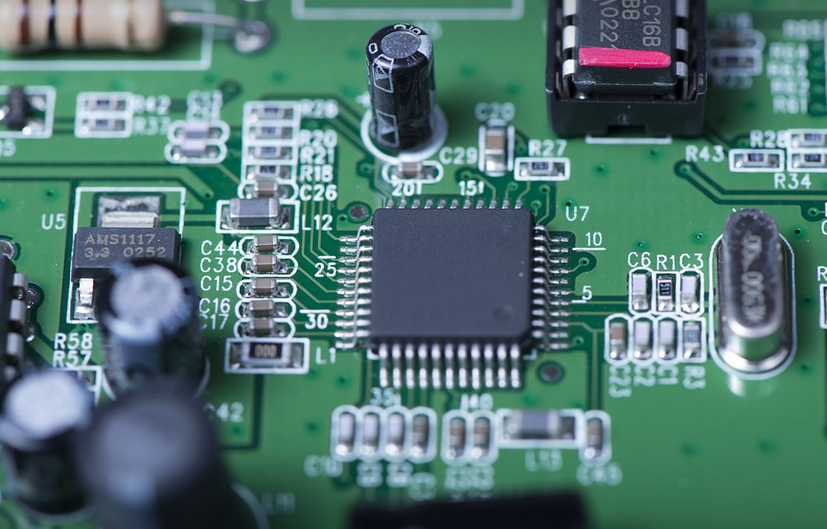

Imagine soldering with the precision of a surgeon, but instead of a scalpel, you’re using a gentle stream of hot air. That’s essentially what a hot air rework station does. These aren’t your kitchen-counter irons; these are specialized tools designed to melt solder and remove unwanted components, all with pinpoint accuracy.

A hot air rework station is like a magic wand for electronics repair. It allows you to work on delicate components without damaging them. This is especially useful when dealing with tiny components or intricate circuits.

Why Choose Hot Air Rework?

There are several reasons why hot air rework stations have become a mainstay in the world of electronics: they offer unmatched precision, speed, and versatility. They can handle soldering jobs that would be impossible to do using traditional methods. Here’s a closer look:

**Precision:** Hot air rework stations provide high-precision temperature control. These tools enable you to adjust the airflow and temperature to the exact needs of your project. This ensures even heating, minimizing damage to delicate components.

**Speed:** Compared to traditional soldering methods, hot air rework stations offer faster processing speeds. They can remove or add components quickly without leaving behind a mess of solder. This makes them ideal for those who work on multiple projects at once.

**Versatility:** Hot air rework stations are not just limited to electronics repairs. You can use them for various purposes, such as removing adhesive residue from products, desoldering components, and even applying heat to plastic components.

**Reliability:** These tools provide a high level of reliability thanks to their robust design and durable materials. This ensures long-term performance even in demanding environments.

**Safety:** The hot air rework station comes with safety features like automatic shutoff, temperature control, and an insulated tip. These ensure that users are protected from any potential hazards during operation.

Key Components of a Hot Air Rework Station

A good hot air rework station is made up of several key components, each serving a specific purpose in the overall process:

**Heating Element:** This component generates the heat necessary for the rework. It usually comes in the form of a long-lasting ceramic element that provides consistent temperature control.

**Air Blower (Fan):** The blower is responsible for sending hot air to your solder tip and ensuring even heating of the components under repair. Different models offer different airflow settings, allowing you to focus on specific areas or larger projects.

**Soldering Tip:** This is a metal tip with a pointed shape, often shaped like a small cone or hook, designed for applying heat to soldered joints or removing parts.

**Temperature Control System (Controller):** This component allows users to precisely set the temperature and airflow of the rework station. It ensures that you are able to adjust your work according to your project’s demands.

**Safety Features:** These include a safety interlock, automatic shut-off function, and an insulated tip to prevent accidental burns.

**Additional Accessories:** Some hot air rework stations come with additional accessories like soldering nozzles, tweezers, and cleaning tools, which can further enhance their versatility.

The Benefits of Using a Hot Air Rework Station

The benefits of using a hot-air rework station extend beyond just speed and precision. These are some of the key advantages of choosing a hot air rework station:

**Precision Soldering:** These stations allow for precise soldering, even on extremely delicate components. The ability to control airflow allows for heat distribution that is less likely to damage sensitive components.

**Faster Repair Time:** Hot air rework stations can streamline your repair process and significantly decrease the time it takes to complete a task. This saves you valuable time and effort while achieving desired results.

**Minimizes Damage:** Since you are not directly applying heat or force, hot air rework stations minimize the potential for damage to components during delicate repairs.

**Versatile Uses:** These stations are not limited to electronics repair alone. They can be used for various purposes like desoldering, removing adhesive residue, and even preheating plastic components for molding.

**Improved Safety:** Hot air rework stations come with safety features that minimize the risk of burns or electrical shocks, ensuring a safer working environment.

**Increased Efficiency:** Working with hot air rework station can help you increase your production efficiency by allowing you to complete tasks faster and more accurately.

Choosing the Right Hot Air Rework Station for Your Needs

Choosing the right hot air rework station depends on several factors, including your budget, specific needs, and the types of projects you work on. Here’s a guide to help you make an informed decision:

**Budget:** Hot air rework stations come in a range of prices, from budget-friendly options to more advanced models. Consider your budget when selecting a station.

**Project Requirements:** The type and complexity of the projects you work on will determine the features you need. A basic model might be suitable for smaller projects, while a more advanced model with higher temperature control and airflow settings could handle larger or more complex repairs.

**Features:** Consider the specific features that are important to you. Some popular options include programmable temperatures, adjustable air flow, automated operation (like automatic shut-off), and built-in cleaning tools.

**Safety Features:** Ensure your hot air rework station comes with safety features such as an automatic shut-off system, a temperature control system, or an insulated tip.

Conclusion: A Valuable Tool for Every Electronics Repair Enthusiast

A hot air rework station is not only a valuable tool for professional electronics repair technicians but also for hobbyists and DIY enthusiasts alike. Its precision, speed, and versatility make it an essential addition to any workshop, allowing you to take on more challenging projects with confidence. The ability to solder delicate components and fix intricate circuits without damaging them makes these stations ideal for anyone who works with electronic devices.