Unveiling the Power of CZ Shadow 2 Slide Milling

In the realm of precision engineering, few technologies have captivated the imagination and fueled innovation quite like slide milling. This versatile machining method has become a fundamental tool in various industrial sectors, offering unmatched control over components, intricate shapes, and highly precise dimensions.

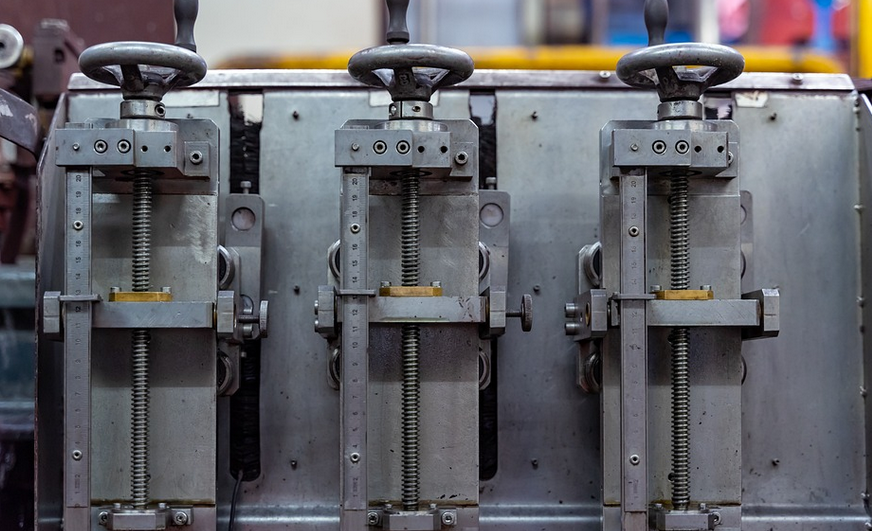

The CZ Shadow 2 Slide Milling machine is a prime example of this technology’s potential. It boasts a compact yet powerful design, empowering users to tackle diverse tasks ranging from small-scale prototypes to large-scale industrial projects.

At its core lies the remarkable capability of the CZ Shadow 2 slide milling machine to precisely move tools along pre-programmed paths. Unlike conventional milling machines that rely on rotation and a fixed cutting process, this innovative system employs a sliding mechanism for superior control over the cutting tool’s trajectory.

Imagine a precise tool moving in precise, controlled steps along the workpiece’s surface, guided by intricate program pathways. This meticulous manipulation leads to exceptionally accurate cuts and smooth surfaces. The CZ Shadow 2 Slide Milling machine stands out from the crowd by delivering this level of precision with remarkable ease.

The benefits of slide milling are numerous and far-reaching. Let’s delve into some key advantages that make this technology a must-have in various fields:

1. Exceptional Precision & Accuracy:

Slide milling delivers unparalleled accuracy thanks to its intricate design and precise control mechanism. This allows for the creation of components with smooth surfaces and tight tolerances, critical for applications demanding high precision, such as aerospace manufacturing, medical devices, and electronics.

2. Enhanced Efficiency & Speed:

Slide milling offers a significant advantage over traditional methods in terms of efficiency. The ability to precisely move tools along intricate paths enables quicker operations, reducing overall processing time. This translates to faster turnaround times for projects requiring greater speed and agility.

3. Versatility & Range of Applications:

The CZ Shadow 2 Slide Milling machine excels in versatility, adapting to a wide range of applications across various industries. From intricate molds and fixtures for automotive manufacturing to micro-scale components used in medical devices, this machine proves its adaptability with its ability to handle diverse projects.

4. Increased Productivity & Output:

Slide milling boosts productivity by minimizing downtime and maximizing output. The streamlined process of accurate cuts and precise movements ensures fewer errors and rework, resulting in increased efficiency and higher production rates.

5. Cost-Effectiveness & Affordability:

While slide milling offers significant advantages, its cost-effectiveness is a major draw for many businesses. The machine’s compact design and efficient operation allow it to be both affordable and accessible, making precision engineering within reach even for smaller companies.

Unlocking the Potential of CZ Shadow 2 Slide Milling: A Practical Guide

For users looking to leverage the power of this innovative technology, a comprehensive approach is essential. Here’s how:

1. Choosing the Right Machine & Software:

Selecting the appropriate machine and software system for your project is crucial. Factors like workpieces’ size, required precision, and desired speeds need to be carefully considered.

2. Mastering the Programming Process:

Programming the CZ Shadow 2 Slide Milling machine to execute precise movements requires specialized skills and expert guidance. The software interface allows users to create intricate algorithms for smooth, controlled cuts.

3. Employing Advanced Techniques:

Beyond basic slide milling, advanced techniques like multi-axis machining can further enhance precision and efficiency. This enables the creation of complex geometries with increased accuracy and detail.

4. Optimizing Workflow & Ergonomics:

Streamlining your workflow is key to maximizing productivity. Proper tool setup, efficient cutting strategies, and ergonomic work practices contribute to a smoother operation, reducing fatigue and ensuring long-term efficiency.

Looking Forward: The Future of Slide Milling

The future for slide milling holds immense promise as technology continues to evolve. New advancements in CNC software and machine automation promises even greater precision, speed, and ease of use.

As we explore the potential of this innovative system, expect to see increased integration with Artificial Intelligence (AI) and Machine Learning (ML). This collaboration will lead to more automated processes, self-optimization algorithms, and enhanced accuracy in cutting.

The CZ Shadow 2 Slide Milling machine is a testament to the ongoing pursuit of precision engineering. Its ability to deliver exceptional accuracy, speed, and efficiency positions it not just as a tool of today but also as a vital part of tomorrow’s technological landscape.