The Old School Charm of Gas Welding

There’s a certain allure to the rumble and roar of a gasoline-powered welding machine, an echo of a simpler time. These workhorses have been around for generations, their smoky trail forever etched in the history of metalworking. Though they may seem like relics of the past, their charm lies in their raw power and unique characteristics.

The heart of a gasoline-powered welder is its internal combustion engine. Just like your car, it utilizes fuel to generate mechanical energy that drives a welding torch. This process differs from electric welders, which rely on direct current and often don’t need external power sources. The distinct sound of an idling engine before striking the first weld is a testament to their robustness.

These machines are all about versatility. They can handle various metals like steel and aluminum, making them suitable for projects ranging from welding pipes in construction sites to repairing delicate metal parts on automobiles. Their ability to produce high-powered heat makes them ideal for heavy-duty work, where the efficiency of electric welders might be lacking.

The control offered by a gasoline welder is another crucial factor. Unlike their electric counterparts, these machines offer greater control over the welding process. Through adjusting gas flow and pre-heating mechanisms, you can fine-tune the heat output for different thicknesses of metal and specific weld requirements. This level of customization allows welders to craft intricate welds with precision.

However, wielding a gasoline welder comes with its own set of challenges. Safety is paramount. The constant exposure to flammable gases requires careful attention and proper ventilation. Using these machines in enclosed spaces can be tricky due to the risks associated with fumes and fire hazards. It’s crucial for welders to wear appropriate safety gear like masks, gloves, and protective clothing, along with working in a well-ventilated area.

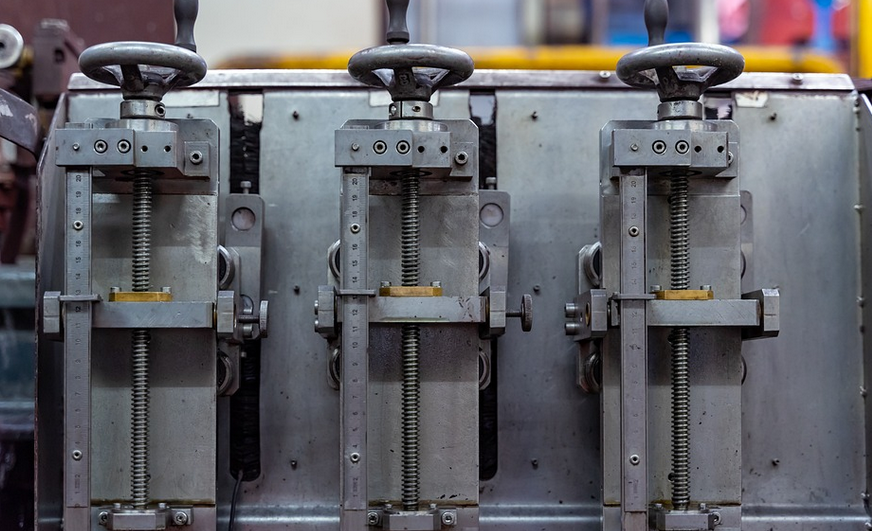

A downside of gasoline-powered welding machines is often their higher maintenance requirements compared to electric ones. Regular servicing, including cleaning, lubrication, and tune-ups are necessary for maintaining optimal performance. The engine needs regular checks and adjustments to ensure consistent operation and prevent potential breakdowns. These tasks can be time-consuming, requiring specialized knowledge and tools.

Beyond the challenges, they offer a unique welding experience that’s difficult to replicate with modern electric machines. The sound of the engine, the feel of the torch in your hands, and the process of watching the weld coalesce are all part of what makes gasoline welders so captivating. It’s a connection to a bygone era, where the act of creating metal was more physically demanding and less reliant on technology.

Another benefit is their timeless design, which often transcends trends. While electric welding machines have become ubiquitous, the rugged aesthetics of a gas welder remain appealing to many. They’re not just tools; they’re pieces of history that can be passed down through generations of welders. This legacy adds to the emotional connection and reverence for these machines.

For those who appreciate vintage craftsmanship and want access to unique welding methods, gasoline-powered welders offer a rewarding experience. They represent a time when metalworking was more about brute force than precision technology. While electric welders provide advantages in terms of safety, control, and convenience, gasoline welders offer a nostalgic appeal and a connection to the history of this versatile craft.

In conclusion, gasoline-powered welding machines are a testament to the enduring power of simplicity and tradition. They might be less common than their electric counterparts, but for those who appreciate a touch of old-school charm and a unique welding experience, they’re truly worth considering.