What Makes a Pipeliner Welding Hood Different?

Welding, especially for large-scale infrastructure projects like pipelines, is an inherently risky occupation. It demands precision and immense skill, but also poses significant safety hazards. That’s where the auto darkening pipeliner welding hood steps in, offering a combination of protection and efficiency that truly elevates the welder.

One of the key reasons for the auto-darkening feature lies in the way it protects against potentially dangerous ultraviolet (UV) and infrared (IR) radiation. While visible light is readily visible, welding generates intense heat and radiant energy that can cause serious burns to skin, eyes, and even internal organs if not properly shielded. These invisible but deadly rays require specialized shielding.

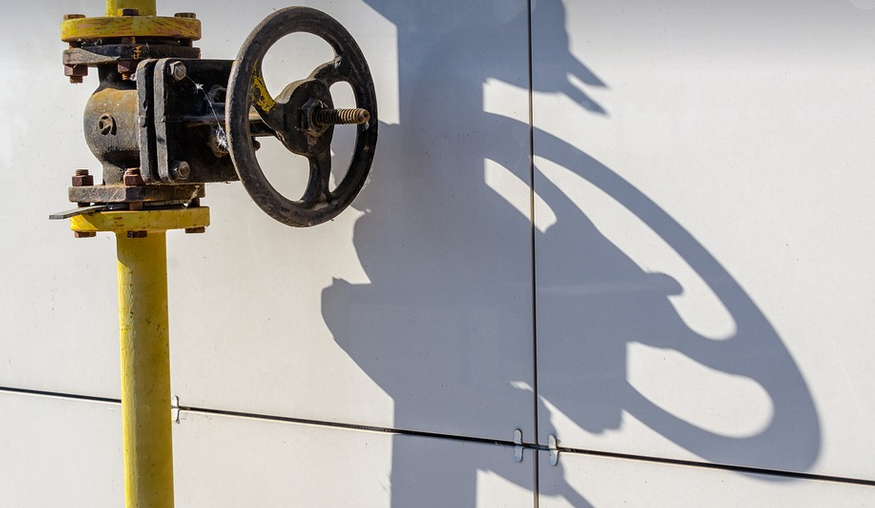

Pipelining involves working in often-confined spaces, with potentially hazardous environments like high pressure pipelines and volatile compounds. A regular welding helmet would struggle to provide adequate protection during these situations. The auto darkening pipeliner hood’s innovative design sets itself apart – it automatically adjusts its shade levels depending on the surrounding light conditions.

How Does This Technology Work?

The magic happens with a cutting-edge technology called “photoelectric sensors”. These sophisticated components are strategically placed within the welding helmet to detect changes in light intensity.

To understand this process, consider this: when you start welding, the sensor is flooded with bright light. The instant your welder turns on, the hood anticipates this change and goes into “dark mode,” darkening its transparent visor to shield your eyes from such intense heat and UV rays. When the shade levels decrease, it automatically switches back to clear viewing.

As you continue welding, if the light intensity fluctuates, the sensors work even faster, switching between dark and clear modes seamlessly. This dynamic automation ensures optimal protection at all times.

The Benefits of Auto Darkening Pipeliner Welding Hoods

Beyond safety, auto darkening pipeliner welding hoods bring a new level of efficiency to your work. Some of the benefits include:

- **Enhanced Accuracy** : The ability to see clearly through the visor allows for precise welding operations, reducing errors and rework.

- **Increased Productivity** : The auto-adjustment feature ensures a seamless transition between dark and clear modes, reducing time spent adjusting shades manually and speeding up the overall welding process.

- **Reduced fatigue** : Auto darkening hoods reduce eye strain by eliminating the need for constant manual shade adjustment. This leads to less fatigue for longer working periods.

- **Improved Weld Quality** : The precise visual clarity provided by the helmet contributes to cleaner welds, reducing defects and rework.

Choosing the Right Auto Darkening Hood for Pipelining

With a plethora of auto darkening welding hoods available in the market, choosing the right one can seem overwhelming. Here’s a breakdown of factors to consider:

- **Welding Position and Application:** Determine what type of welding you are performing – TIG, MIG, stick or arc welding.

- **Environment and Safety Regulations:** Consider the work environment, including the presence of fumes, gases, dust and potential for sparks. Check local safety regulations about required certification.

- **Hood Size and Fit:** It’s crucial to ensure a comfortable fit and proper coverage around your head.

- **Battery Life:** Some hoods use more powerful batteries than others, so consider how long you’re exposed to welding before needing a recharge.

Auto Darkening: A Revolution in Welding Safety

The auto darkening pipeliner welding hood has become an indispensable tool for welders working on pipelines and other high-risk construction projects. It’s not just about safety, it’s about empowerment for the welder. By automating the process of shade adjustment, auto darkening helmets give welders more control over their environment while ensuring optimal safety during welding operations.