What is an HDPE Pipe Welding Machine?

Think of a pipe welding machine as the culinary artist’s trusty tool, transforming raw materials into something truly functional and beautiful. In the world of piping for applications like water supply systems, drainage, and even chemical processing, this magic wand takes on the challenge of joining high-density polyethylene (HDPE) pipes together with precision and strength.

The Magic Behind the Machines

The process starts with a carefully crafted HDPE pipe. These pipes are known for their resilience to harsh weather conditions, corrosion resistance, and cost-effectiveness thanks to their ability to be manufactured from renewable resources. But how do you join them together efficiently and effectively? Here’s where the power of these machines comes in.

HDPE pipe welding machines leverage powerful technological advances to achieve precise welds that hold up under pressure. These machines are essentially a combination of controlled heat, specialized tools, and intricate expertise. They utilize high-frequency electric currents or laser beams to melt the edges of HDPE pipes together seamlessly. The result is a robust joint with unparalleled strength, comparable to the original pipe itself.

Types of HDPE Pipe Welding Machines

Just like there are various tools within a toolbox, the world of HDPE pipe welding machines offers diverse options, each tailored for specific needs and applications. Let’s explore some prominent types:

* **Torch Welding Machines:** These workhorses, often utilizing oxygen and acetylene torches, melt the edges of the pipes together directly, generating heat to create the weld joint. They are known for their simplicity and cost-effectiveness but require skilled operators and careful attention to detail to avoid blowouts or incomplete welds.

* **Rotary Welders:** Imagine a rotating wheel that moves the pipes while simultaneously applying high-frequency welding currents. This method delivers consistent, reliable welds with increased speed and efficiency. Though initially costly to acquire, these machines quickly pay for themselves through their productivity gains.

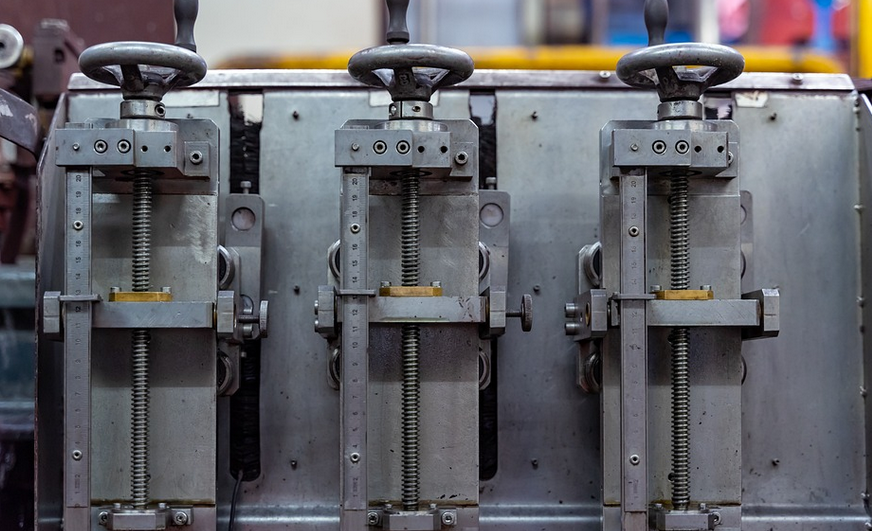

HDPE Pipe Welding Machines: A Closer Look at Their Functionality

To delve deeper into the workings of these machines, let’s examine some key features that contribute to their functionality:

* **Precision Positioning:** These machines utilize sophisticated controllers and robotic arms with remarkable accuracy. The machine ensures a precise fit between both pipes for strong welds.

* **Controlled Heat Generation:** The ability to precisely control the temperature and duration of heat application is critical. Modern welding machines allow for this through advanced feedback systems and adjustments for different pipe thicknesses and materials.

Applications: Where HDPE Pipe Welding Machines Shine

HDPE pipe welding machines have a versatile range of applications, catering to various industries:

* **Water Supply Systems:** From residential homes to large-scale municipal systems, these machines are used to join pipes for efficient water distribution and even wastewater management.

* **Irrigation Systems:** Keeping crops thriving requires connecting pipes for irrigation. These machines ensure robust and leak-proof connections in agricultural settings.

* **Drainage Networks:** Ensuring smooth drainage for homes and businesses relies on the expertise of HDPE pipe welding machines to construct and maintain effective drainage systems.

The Future of HDPE Pipe Welding Machines: Embracing Innovation

As technology advances, so too will the capabilities of HDPE pipe welding machines. We can expect to see even more innovative tools that offer greater precision, faster speeds, and reduced waste in the years to come:

* **Automation:** Imagine a future where automated systems handle welding tasks with unparalleled accuracy and efficiency, eliminating human error and increasing production speed.

* **AI-Driven Welding:** The integration of artificial intelligence into these machines has the potential to optimize welding parameters based on real-time inspection data. This allows for even higher-quality welds, reducing waste and improving long-term performance.

Embracing Sustainability:

One particularly exciting aspect of HDPE pipe welding machines is their contribution towards environmental sustainability.

* **Renewable Materials:** Using HDPE pipes eliminates the need for harmful materials like asbestos, significantly reducing environmental impact.

* **Long Lifespan and Reduced Maintenance:** HDPE’s durability translates to longer-lasting systems with minimal maintenance requirements. This lowers overall energy consumption and reduces waste generation.

Conclusion: The Power of Precision for a Sustainable Future

HDPE pipe welding machines have revolutionized the way we design efficient, durable plumbing systems. Their precision, accuracy, and versatility ensure long-lasting solutions that meet the demands of modern infrastructure. As technology continues to advance, these machines will play an even larger role in shaping a sustainable future.

With their ability to deliver high-quality welds and minimize waste, HDPE pipe welding machines are poised to become indispensable tools for engineers, contractors, and anyone involved in the construction of robust and long-lasting infrastructure.