What is Metal Fabrication?

Metal fabrication, in its essence, is about taking raw metal—be it steel, aluminum, copper, or even titanium—and transforming it into useful objects. It’s like giving a piece of metal a specific purpose and shape. It’s not just about cutting, welding, and shaping; it’s about bringing together creativity and precision to create something tangible.

Think about the iconic Eiffel Tower, a masterpiece of ironwork that stands in Paris today. Or perhaps the gleaming skyscrapers dotting our cities – these buildings are testaments to metal fabrication’s power to shape the urban landscape. These structures wouldn’t be possible without expert metal fabricators who can manipulate raw materials into precise forms.

Metal fabrication encompasses a wide range of processes, each tailored for specific applications and desired outcomes. It can involve cutting, bending, drilling, stamping, welding, and more – all meticulously executed to achieve the intended design. Imagine a car manufacturer using precision tools to create intricate metal components that power the vehicle, or an architect carefully crafting beams and columns from steel bars for an impressive structure.

From everyday objects like furniture and appliances to complex machinery and military equipment, metal fabrication plays a vital role in numerous industries. It’s in our kitchens with the washing machine’s chassis, in our homes with the intricate railing of our balcony, and even in our vehicles, where every part is designed and made to function seamlessly together.

What is Welding?

Welding is a fundamental process within metal fabrication that joins metals by applying heat or pressure. It’s all about merging two pieces of metal into one solid unit. This might sound simple enough, but the process requires specific techniques, specialized tools, and meticulous attention to detail to ensure a strong, lasting weld.

Think of welding like creating a bridge between two separate pieces of metal. It joins them together, leaving behind a seamless connection that can withstand significant forces. A well-executed weld is practically invisible; it blends seamlessly with the metal’s natural surface and creates an unbreakable bond.

There are many different types of welding processes, each with its unique strengths and applications. There’s MIG (Metal Inert Gas) welding – known for its versatility and ability to work on various thicknesses of metals; TIG (Gas Tungsten Arc Welding) is used for delicate jobs where precision is paramount; and Stick welding uses an electrode to join the pieces, often in industrial settings.

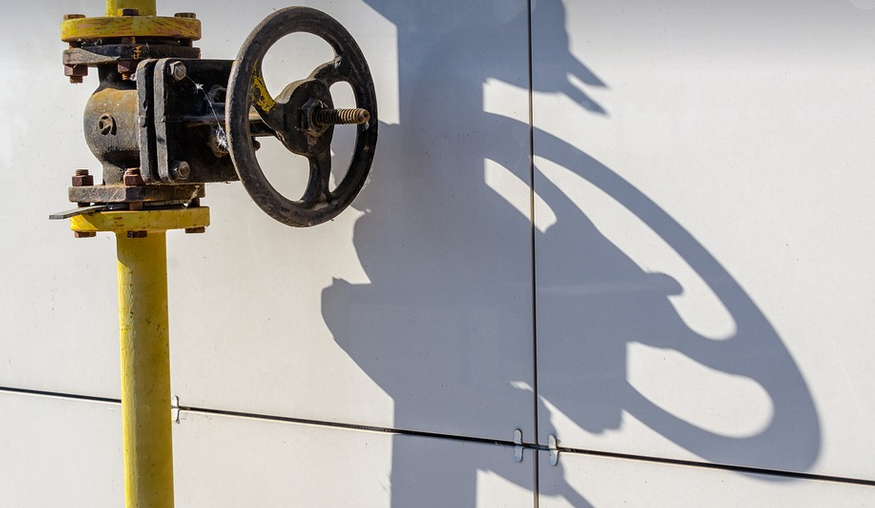

Welding is essential in a wide range of industries. From constructing skyscrapers to building bridges, from crafting machinery for automobiles to repairing pipelines for energy production, it underpins countless engineering projects that shape our world.

The world of metal fabrication and welding might seem complex at first glance. But the truth is, it’s about shaping the world around us one piece at a time. From intricate jewelry to massive structures, from everyday gadgets to cutting-edge advancements, this blend of creativity, precision, and technology continues to inspire innovation across countless fields.