What is a Vertical Knee Milling Machine?

A vertical knee milling machine, often simply called a “knee mill,” is a powerhouse in the world of woodworking and metalworking. Imagine a sturdy workhorse with a powerful engine, capable of tackling intricate projects with precision. This machine has been a staple in workshops for decades, and its reputation for reliability and versatility speaks volumes about its functionality. But what exactly makes it tick?

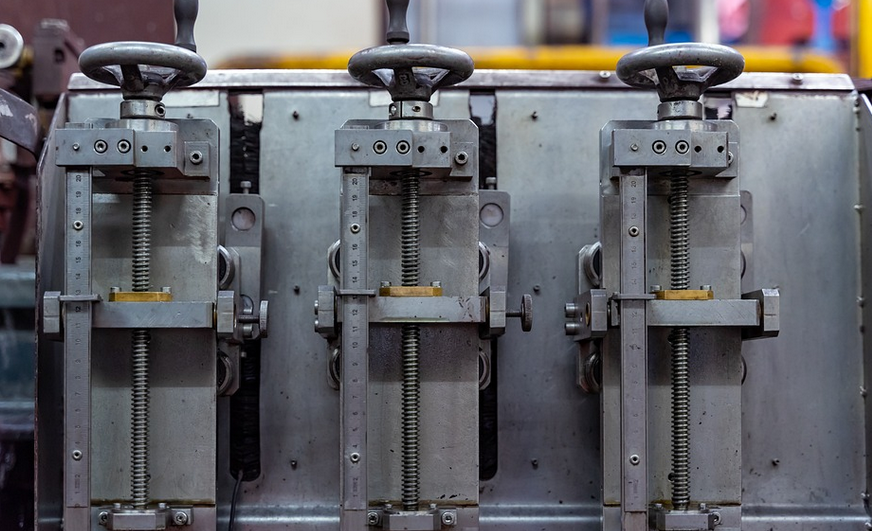

The defining feature of a vertical knee milling machine is its unique structure. It features a large horizontal table where you place your work pieces – think of it like an assembly line – and a vertically movable “knee” (or column) that acts as the driving force for cutting. This knee, located at the center of the machine’s frame, moves back and forth, allowing the spindle to follow a specific path and create precise cuts.

The magic happens when you combine the power of this vertical motion with a spindle. The spindle is like the heart of the machine, responsible for holding the cutting tool and spinning it at high speeds. When you lower the knee, the spindle slides through the workpiece in a predetermined path. The knee’s movement allows for both precise depth cuts and complex curves as needed.

The Advantages of a Vertical Knee Milling Machine

This machine offers a multitude of benefits over other milling options: its powerful mechanics, high accuracy and precision, and adaptability make it ideal for various tasks.

**Precision:** The vertical knee system guarantees precise cuts across a wide range of materials. This is especially important when dealing with delicate parts or intricate designs. Without the need for complex alignments and adjustments like you might find in other milling machines, vertical knee machines deliver consistent results.

**Versatility:** Vertical knee mills are incredibly versatile. They can handle both large and small projects, from woodworking to manufacturing. This makes them an invaluable tool for any workshop or facility operating a machine shop.

**Speed and Efficiency:** These machines boast speed that comes with their powerful mechanics, allowing you to get your job done faster – which translates into more productivity and less downtime during production.

The Types of Vertical Knee Milling Machines

To cater to diverse needs and projects, vertical knee milling machines come in various forms.

**General Purpose:** A perfect choice for beginners or those requiring a machine that can handle a wide range of tasks. These models are known for their versatility and ease of use.

**Heavy Duty:** Designed to tackle the most demanding projects. These machines boast power and robustness, capable of handling heavy materials and high-volume production.

**CNC Machines:** These machines combine the precision of a vertical knee machine with advanced CNC technology for automated work. They offer even greater control and precision, allowing for intricate designs and complex cuts.

Choosing the Right Vertical Knee Milling Machine

The best way to choose the right machine is through careful consideration of your specific needs and requirements.

** Workload:** Think about the projects you plan on tackling. Will you be primarily working with wood, metal, or both? Knowing this will help narrow down your options.

**Budget:** Vertical knee milling machines can range in price depending on features and capabilities. Determine your budget before starting your research.

**Features:** Look for machines that prioritize the features you need most: power, speed, accuracy, or even programmable automation.

The Future of Vertical Knee Milling Machines

As technology advances and manufacturing demands evolve, the world of vertical knee milling machines continues to see innovation and development.

**Automation:** With CNC technology and advanced control systems, new models are being developed with increased automation capabilities, making it easier for beginners to learn and operate these powerful machines.

**Sustainable Solutions:** The future holds a greater focus on sustainability in manufacturing. Vertical knee machines continue to evolve with greener solutions, like utilizing energy-efficient motors and incorporating recycled materials into their construction.

Whether you’re a seasoned professional or an aspiring DIYer, the vertical knee milling machine is a powerful tool that can help you achieve your crafting goals with precision and efficiency.