Understanding the Basics of Trailer Frame Construction

Building your own trailer frame can be a rewarding DIY project, offering you complete control over its design, functionality, and aesthetics. But before you dive into welding those sturdy metal pieces together, it’s crucial to grasp the fundamentals of trailer frame construction.

Let’s start with the essential elements that make up a typical trailer frame: * **Frame Material:** Traditionally, steel is the go-to material for trailer frames due to its strength and durability. However, aluminum is gaining traction in recent years, offering lighter weight and reduced corrosion issues.

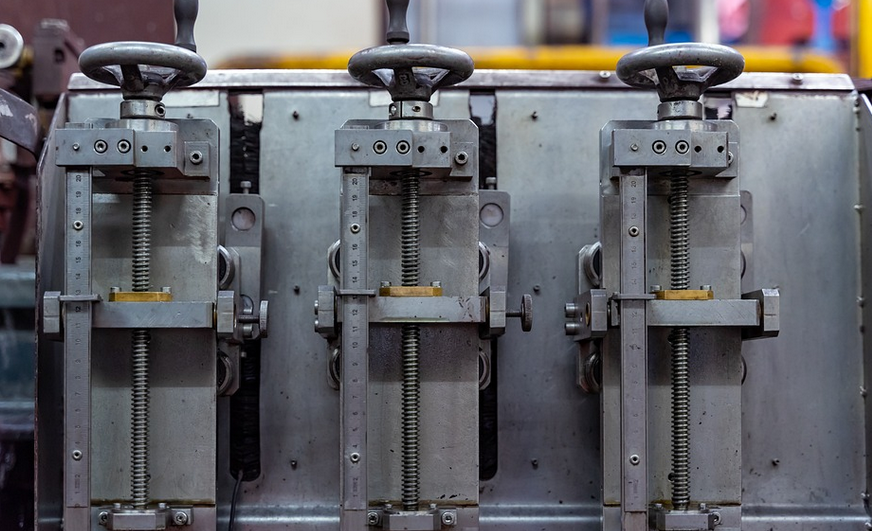

**Crossmember Construction:** The crossmembers are the backbone of your trailer frame, providing crucial support for the load-carrying capacity. They’re typically made from steel and positioned strategically to distribute weight evenly across the trailer’s length. Two main crossmember designs stand out: a single-piece crossmember or a multi-piece approach.

**Cantilevered Construction:** This design further enhances load distribution by extending outward from the frame, leading to increased stability and load capacity. It’s particularly useful for heavier trailers where you need to accommodate bulky cargo or heavy weights.

**Suspension System:** A well-designed suspension system is vital to ensure your trailer rides smoothly, absorbs bumps in the road, and maintains optimal contact with the load. The type of suspension you choose will impact handling, weight distribution, and fuel efficiency.

**Braking System:** Safety must always come first. A reliable braking system ensures secure stopping power for your trailer and is crucial when hauling heavier loads.

**Understanding Welding Techniques:**

Welding plays a vital role in creating the seamless joints necessary to construct a sturdy and durable trailer frame. The welding technique you choose will depend on several factors, including the type of construction, desired aesthetics, and budget constraints.

**Spot Welding:** Spot welding is an exceptionally strong method for joining metal sheets. It involves using a high-frequency electric current to create localized weld points. This process produces clean welds with minimal distortion, making it ideal for trailer frame applications.

**Seam Welding:** This technique uses a continuous welding process that creates smooth, continuous welds along the edges of a frame section. It’s widely used for steel trailers due to its efficiency and cost-effectiveness.

**MIG (Gas Metal Arc) Welding:** MIG welding is another popular choice for trailer frames. It offers good penetration depth and weld quality while requiring minimal training. The process utilizes a continuous wire feed to create the welds.

**TIG (Gas Tungsten Arc) Welding:** TIG welding requires more skill than other methods, but it’s regarded as the most precise method for joining metals. It uses a tungsten electrode to create a high-quality, controlled weld at each joint.

**Choosing the Right Welding Equipment**

Selecting the correct welding equipment is crucial for ensuring efficiency and safety throughout your project. Here are some of the essential things to consider when choosing welding equipment:

**Welding Machine:** The welding machine provides the electrical current needed to melt the metal and create the weld. Look for a machine with high power output, adjustable voltage control, and robust features suitable for trailer frame construction.

**Welding Electrode/Wire:** The right electrode or wire type will impact weld quality and performance. Ensure you choose an electrode designed specifically for your welding technique (e.g., MIG, TIG).

**Protective Gear:** Welding is a potentially hazardous activity, so always wear appropriate protective gear, including welding gloves, helmet with proper shade rating, and safety glasses to protect against sparks, heat, and harmful fumes.

**Step-by-Step Guide to Welding Trailer Frames**

Now that we’ve covered the fundamentals let’s dive into the step-by-step process of welding a trailer frame:

1. **Prepare the Frame Sections:** Begin by cleaning and preparing each metal section before welding. Remove any rust, oil or grease to ensure proper weld penetration.

2. **Preheating the Metal:** For certain metals, preheating can improve weld quality. This process involves heating the metal sections slightly before welding to soften the material and reduce the risk of cracking.

3. **Welding Technique Selection:** Choose the appropriate welding technique based on your desired weld pattern, design complexity, and skill level.

4. **Proper Welding Position:** Ensure you’re using a stable and secure work position to avoid accidents or unintended movements during welding. Consider using clamps or other tools for holding metal pieces together securely while welding.

5. **Maintain Consistent Weld Parameters:** For optimal weld quality, maintain consistent welding parameters like current, voltage, wire speed, and electrode size throughout the entire welding process.

6. **Tack Welding:** Before completing a final weld, consider using tack welds to secure the pieces together temporarily before applying stronger welds later. This avoids movement or distortion.

7. **Finishing Touches:** Once complete, apply any necessary finishing touches after welding. This might involve grinding down extra metal for a smoother finish or even painting the trailer frame to protect it from corrosion.

**Post-Welding Maintenance and Safety**

After welding your trailer frame, ensuring proper maintenance will extend its lifespan and prevent future issues. Here’s what you should consider:

**Rust Prevention:** Apply rust inhibitors or sealants to the frame sections to prevent moisture accumulation and prolong its lifespan. Regular cleaning and washing are also essential for maintaining a clean and corrosion-resistant surface.

**Protective Coating:** Applying a protective coating like epoxy paint can further protect the trailer frame from environmental damage, rust, and scratches.

**Storage and Handling:** Store your newly welded trailer in a dry and sheltered space to minimize exposure to moisture and potential weather damage. Ensure you handle the trailer with care when moving or transporting it.

**Safety First:** Always prioritize safety throughout the process of welding. Use appropriate personal protective equipment like gloves, helmets, and goggles to avoid contact with sparks, heat, or hazardous fumes.

**Conclusion: A Well-Built Trailer for Years to Come**

Building a trailer frame from scratch requires dedication, patience, and proper planning. By following these steps, you’ll be well on your way to constructing a sturdy, reliable trailer that is ready to tackle your next project.

Remember, the journey of building anything takes time, effort, and attention to detail. But with careful planning, the right tools, and a commitment to safety, you can create a well-built trailer for years to come.