What’s the Hype About 2000W Laser Welding?

Laser welding, a technological marvel in the world of manufacturing and engineering, is becoming increasingly prevalent. 2000W laser welding machines are a big part of this surge in popularity, offering a powerful and precise solution for various industries. But what exactly makes them special?

Unlocking Precision: The Science Behind Laser Welding

Laser welding works on the principle of focused light energy. A highly concentrated beam of light strikes the metal surface with pinpoint accuracy, generating heat without damaging surrounding materials. This focused heating allows for a precise melting point, minimizing excess heat and reducing material distortion.

Think of it like this: Imagine trying to weld two pieces of metal together using a regular welding torch. You’re likely to encounter some warping or unevenness in the joint, right? With laser welding, you’re focusing the energy directly onto the intended seam, minimizing these effects and achieving smoother welds.

The Power Behind the Beam: Understanding 2000W

A 2000W laser welding machine packs a punch. This represents a significant amount of power that translates to faster welding speeds and increased productivity for manufacturers. With this much energy at hand, you can weld through thicker materials like steel or aluminum more easily than ever before.

Imagine welding a metal sheet half an inch thick! 2000W lasers enable precise seam creation on even the most substantial parts with minimal time investment.

The Benefits of Laser Welding: Efficiency and Precision in One

Laser welding machines are more than just powerful tools; they’re efficiency powerhouses. They offer a range of advantages that other methods, like traditional welding, can’t match:

- **Speed:** Laser welding is much faster than traditional techniques. The process involves only heating the seam, leaving the rest of the material untouched.

- **Precision:** 2000W lasers deliver excellent control over the welding point, ensuring accurate and consistent welds with minimal distortion.

- **Versatility:** These machines are capable of handling various metals like steel, aluminum, copper, and more. They can even be used to weld different thicknesses of materials.

- **Less Waste:** The laser’s focus minimizes heat and material consumption, reducing waste compared to traditional welding methods.

- **Cleanliness:** Laser welding leaves behind minimal debris, making for a cleaner process with less cleanup time.

2000W Laser Welding: A Key in Manufacturing’s Future

The world of manufacturing is constantly evolving. New technologies are emerging to streamline processes and enhance efficiency. The adoption of laser welding, especially the use of powerful 2000W machines, is a testament to this evolution.

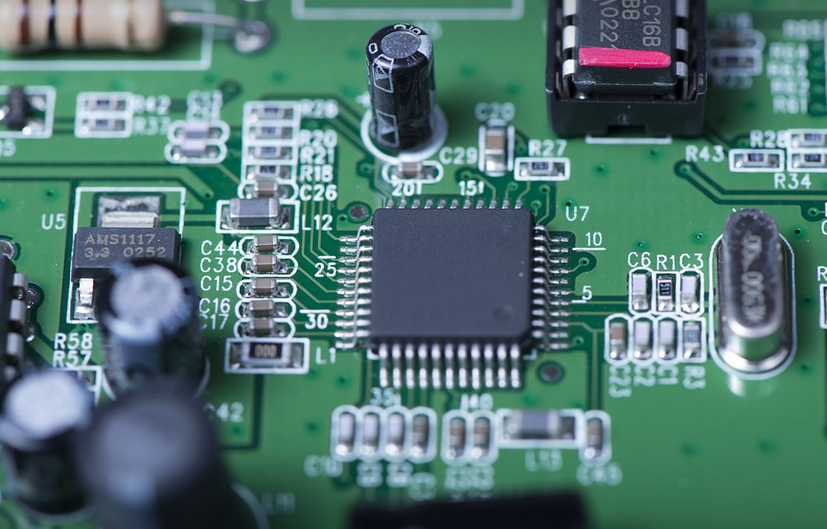

Manufacturers across various industries, from automotive and aerospace to electronics and medical equipment, are leveraging these advancements to boost their production rates and deliver higher-quality products. The precision, speed, and versatility offered by laser welding are paving the way for future innovations in manufacturing.

As technology evolves, we can anticipate even more impressive applications of laser welding machines in different sectors. 2000W lasers are a testament to this ongoing progress, driving innovation in the world of technology and contributing to a brighter, more efficient future for manufacturing